Mk8 EGA EVO

MK8 EGA EVO

Overview: CEMS emissions auditing and trim control

For decades, boilerhouses, manufacturing plants and other industrial environments have used EGA’s (Exhaust Gas Analyser) to monitor flue emissions to comply with environmental regulations & to reduce fuel usage & emissions. The EGA EVO can operate as a standalone independent continuous monitor, or it can feed back its readings to an Autoflame MM Boiler Controller, allowing the MM to adjust the fuel/air ratio (trim) of the burner for optimised performance

Perform simultaneous and continuous sampling of six exhaust gases, including O2, CO2, CO, NO, NO2, and SO2, at a significantly lower cost compared to alternative systems. This capability can be utilized either in conjunction with the Autoflame MM Controller or as a standalone mode

The MM Controller now offers enhanced fuel efficiency and emission reduction through its newly integrated 3-parameter trim control feature. Additionally, the system comes equipped with CEMS Auditing software, which allows users to access comprehensive reports over user-defined time intervals, such as 24 hours, 2 weeks, 1 month, 2 years, and more. These reports encompass critical

Total weight and volumetric emissions

Weight/volumetric emissions per exhaust

The overall cost of fuel consumed during the specified periods

Mk8 EGA EPA Conformance

The annual service for the Autoflame EGA involves a comprehensive procedure, encompassing cleaning, recalibration, and a thorough inspection to identify any potential faults. This service can be availed by customers for their EGA units, which can be sent for maintenance to two convenient locations: our UK Manufacturing Headquarters or our affiliated partners in the USA, known as Midwest Combustion

Main Features

Continuous Emissions Monitoring

Monitor & Reduce Boiler Emissions O2, CO2, CO, NO, NO2, SO2 Analysis

Temperature, Pressure, H2O content

Stores 3 Years of Emissions Data 3 Parameter Combustion Trim

Maintain Safe, Efficient Combustion 12” HD Touch-Screen

Safe Combustion Limits Emissions Data Totalisation

Extract All Data to PC Instantly Live

Emissions Reporting Modbus Connectivity

EPA Self Calibration Model

Proven Over 30+ Years

Ideal for Boilers, Diesel Engines, kilns, Dryers & Generators

MCPD Compliance

Integrated, Cost Effective Solution

Operating as a Standalone unit or with Autoflame Mk8 or Mini Mk8 MM

Specifically designed for current regulations on emissions monitoring

12.1” multi-touch full colour screen

Stored information is updated every minute

Mk8 EGA Evo Servicing and Calibration

Simultaneous & continuous sampling of up to 6 exhaust gases (O2, CO2, CO, NO, NO2 & SO2) at a fraction of the price of alternative systems. Use with Autoflame MM Controller or Standalone Mode

Enables 3 parameter trim control in MM Controller for improved fuel efficiency and emission reduction. With built-in CEMS Auditing software, view reports by user-definable time periods (24 hours, 2 weeks, 1 month, 2 years, etc.) based on

Total weight & volumetric emissions

Weight/volumetric emissions per exhaust

Total cost of fuel

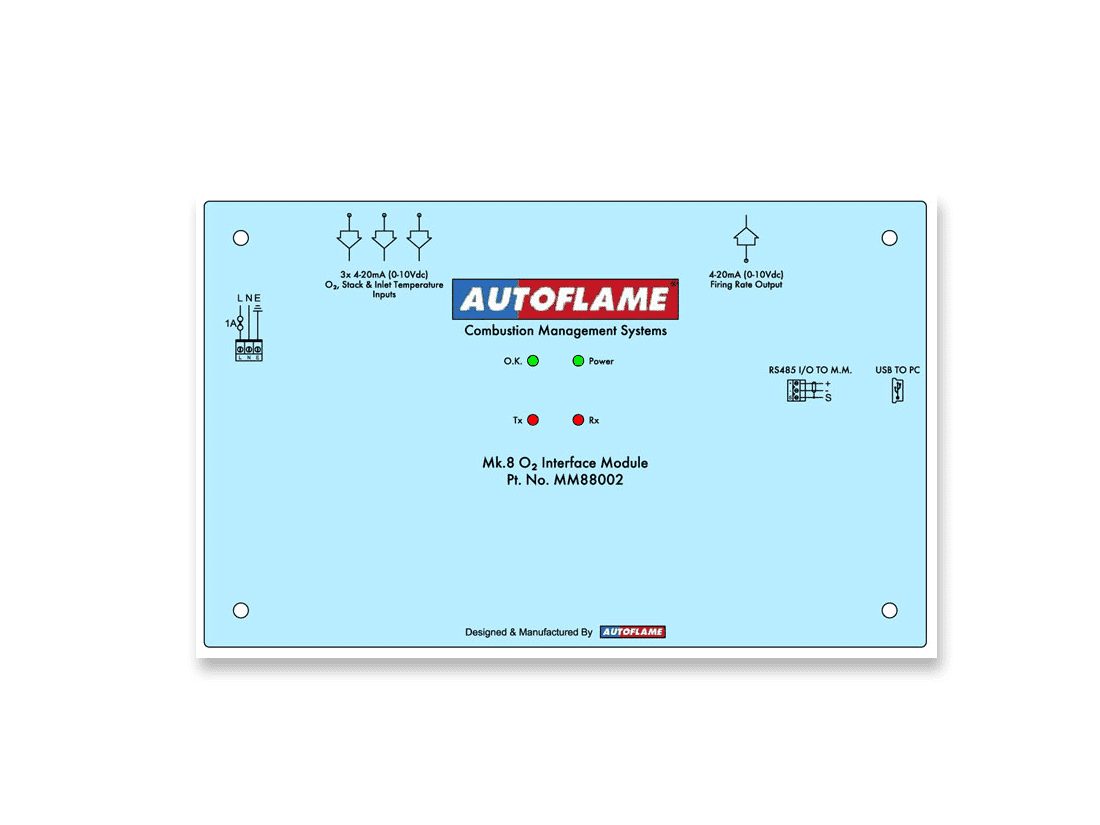

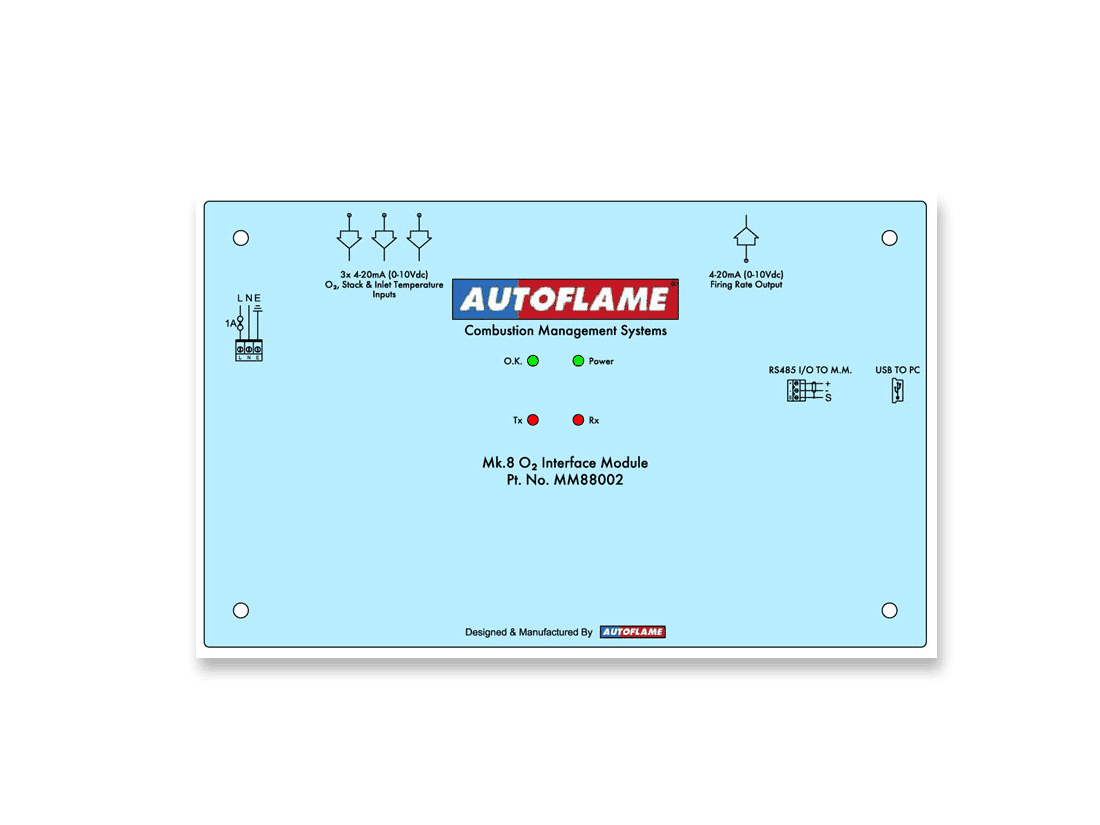

Mk8 O2 Interface

This module enables O2 trim with Mini Mk8 and Mk8 MM Controllers for limited budget applications. We generally recommend the Mk8 EGA Evo instead, as it enables a more advanced 3 parameter trim.

O2 interface setup

The default configuration for inputs and output 1 is 4-20mA, (0-10Vdc can also be used)

Inputs 2 and 3 are set to 150ºC and 20ºC as default, (4-20mA or 0-10Vdc can also be used)

Analogue Input 1 – O2 Signal Input

Analogue Input 2 – Stack Temperature Input

Analogue Input 3 – Inlet Temperature Input

Analogue Output 1 – Firing Rate Output